GROUP PACKING MACHINES

Use environmentally friendly secondary packaging machines to package your products automatically for transport and display

Orfer’s wrap-around group packing machines automatically pack individually packed products into group packaging for transport and display. The machine places the products in groups, which are transferred on a corrugated cardboard blank for wrapping and closing by using hot glue.

Group packing machines are equipped with a product-specific grouping module, which is adapted according to the client’s products and need. Group packing machines with a wider frame are also available.

Automatically formed secondary packaging saves packaging materials and make logistics more efficient. Orfer’s group packing machines are designed and manufactured in Finland.

Efficient and environmentally friendly shelf-ready

packaging solutions for transport and shelving at stores

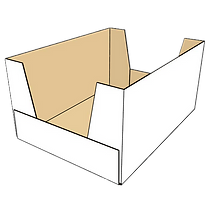

Wrap-around boxes

Trays

High trays

Contact us when you want more information about the properties of our group packing machines

Frequently asked questions about Orfer’s group packing machines

What kinds of packaging can be formed by using the group packing machines?

Orfer’s group packing machines can be used for various FEFCO box designs. Our specialists help you find the right packaging solution, even if you don’t know the FEFCO code of the group package.

What is the size of packaging produced by Orfer’s group packing machines?

Tray sizes: Minimum packaging size 230 x 80 mm, maximum packaging size 500 x 400 mm Dimensions of the wrap-around boxes: Minimum packaging size 230 x 80 mm, maximum packaging size 450 x 400 mm

What kinds of premises are suitable for group packing machines?

Indoor production premises are suitable for group packing machines. You should reserve at least 10 m2 of floor space for the machine, depending on the machine model. In addition, reserve approximately one meter around the machine in all directions. The height of the group packing machines is approximately 250 cm. The indoor temperature should be +3–30°C. The normal humidity in the production premises should not exceed the dew point. Otherwise, this should be mentioned to our specialist. We do not provide solutions for ATEX premises (explosive atmospheres).

Can the machines withstand dust, and can they be cleaned?

The reliability and long lifecycle of Orfer’s group packing machines are a given for us. The special requirements of the operating environment are taken into account in the design of the machines. The benefits of Orfer’s group packing machines include usability, easy cleaning and serviceability.

What is the capacity of Orfer’s group packing machines?

The product, product group and product variation are the biggest factors affecting the capacity. Our machines automatically adapt to the line speed. Our specialist will help you find the machine best suited for your needs.

For what kinds of hygiene requirements are Orfer’s machines suitable?

Secondary packaging and intralogistics solutions are our core expertise. We ensure compliance with hygiene requirements when processing secondary packaging for food products.

What happens in the case of a failure?

The packing machine stops in a controlled manner in the case of a failure. The machine indicates the failure status by means of a light beacon and on the touchscreen, giving instructions on how to proceed. After the machine has come to a standstill in a controlled manner, the electric lock of the door will be released, and the failure can be cleared safely. The machine uses a soft start to continue production rapidly, making any unplanned standstills shorter. Orfer also offers the oCare 24/7 remote support service.

Where are Orfer’s group packing machine manufactured?

Orfer’s automation solutions are designed, manufactured and tested in use in Finland. We only use responsible cooperation partners.

Can the user interface be modified?

Orfer’s informative user interface can be modified to provide the required languages and user levels.

How long does it take to change the packaging size?

The machines include an adjustment mechanism and switching programs for rapid changing. Changing the product size typically takes approximately 15–20 minutes. Automatic size changing is available as an option for the group packing machines, shortening the time required for adjusting the product size.

What does SRP packaging mean?

Wrap-around boxes are very often SRP boxes, or shelf-ready packaging. This means that the transport packaging becomes a display packaging when unnecessary sections are removed along the perforated lines during shelving.

.jpeg)