Five Proven Ways to Extend the Lifecycle of a Packaging or Palletizing System Through Modernizations

- Mikko Arponen

- Oct 9, 2025

- 3 min read

When an automation system starts showing signs of wear, a company has two options: invest in a completely new system or extend the lifespan of the existing one through smart modernization. According to Toni Pesonen, Technical Sales Manager at Orfer Services, most customers choose the latter.

Here are the five most common ways to extend an automation system’s lifecycle — and the reasons why it makes sense.

1. Software Updates and Optimization

The most cost-effective way to extend system life is to modify the software. Unnecessary functions can be removed and new ones added, enabling higher production efficiency without major investments or lengthy production downtime.

2. Replacing Grippers

Product packaging evolves over time. Modern grippers ensure reliable product handling and help prevent unnecessary stops in production.

3. Updating Safety Devices

Older cells don’t always meet today’s safety standards. Door safety interlocks, light curtains, and safety circuits are all crucial elements for ensuring safe machine operation. Alongside staff training, safety updates reduce the risk of accidents and potential liability costs.

4. Renewing the Robot, Control Logic, and User Interface

When spare parts for existing equipment become difficult to obtain, it’s time to plan a modernization. A proven approach is to renew the control logic and user interface—often together with the robot itself. This improves usability and opens interfaces for data utilization.

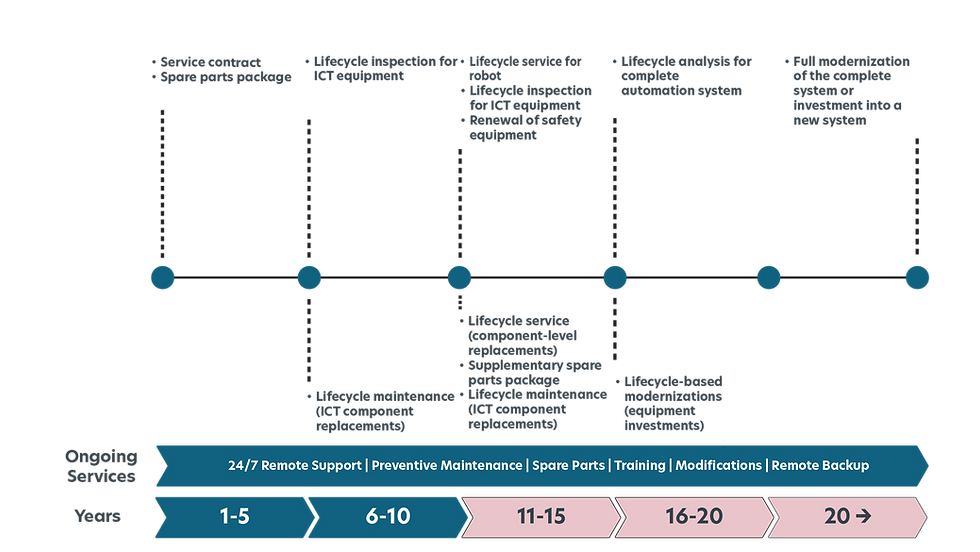

These modernizations can be carried out in stages, making it easier to integrate them into maintenance or production budgets.

5. Replacing Individual Components

In some cases, replacing only critical components nearing the end of their lifecycle is sufficient. This keeps the system operational while ensuring the continued availability of spare parts.

When Is It Time to Modernize?

Recurring failures, rising maintenance costs, and difficulties obtaining spare parts are clear warning signs. Production changes can also trigger the need for upgrades — for instance, when the original system no longer meets current production requirements.

Modernization doesn’t have to happen all at once; projects can be divided into phases, spreading the costs over time. Orfer minimizes production downtime through careful scheduling and phased execution.

A Practical Example

One of our clients in the food and beverage packaging industry invested in a 51-station robotic palletizing system back in 2005.

Despite running three shifts daily, the system remained mechanically sound. However, its control technology was nearing the end of its lifecycle, and spare parts were no longer guaranteed.

The modernization was carried out in phases. First, the old Mitsubishi control logic was replaced with a widely used Siemens safety PLC. This gave the client’s in-house team the ability to make software adjustments themselves and ensured long-term spare part availability.

The next challenge involved robots and grippers that had reached the end of their technical life. When the client switched from tape-sealed to glue-sealed boxes, the original grippers could no longer grip properly—causing frequent interruptions.

The solution was to replace the palletizing cell’s robots and equip them with modern grippers that can reliably handle glue-sealed boxes.

As a result, the client’s palletizing system gained several more years of operational life.

Through small, phased investments, the company avoided a costly full replacement and ended up with a system that performs like new—more reliable, efficient, and ready for future production needs.

Key Benefits of Modernization

Fewer failures and unplanned production stops

Reduced maintenance costs

Improved energy efficiency through new components

Better usability and integration with higher-level systems

Compliance with current safety directives

Looking Ahead

Automation and robotics are advancing rapidly. Modernization provides companies with a bridge from the present to the future—it enables the use of new interfaces, better data collection, and readiness for upcoming automation needs.

A smart modernization not only extends the life of an existing system but also turns it into a competitive advantage for years to come.

“Many companies need to update their systems after a long investment break. Modernization offers a cost-effective way to upgrade technology and ensure continuous production without long interruptions,”

summarizes Toni Pesonen.