Benefits of Wrap-Around Packaging Machines

- Mikko Arponen

- Aug 8, 2025

- 6 min read

Modern manufacturing industry faces continuously growing demands. Cost-effectiveness must be improved, production must adapt flexibly to changing consumption habits and packaging sizes, while companies must respond to tightening environmental regulations and workforce availability challenges. In this demanding operating environment, the right technology choices are key. One significant solution for end-of-line production efficiency is the wrap-around packaging machine, which offers concrete benefits from material efficiency to operational reliability.

Benefits: Wrap-Around Packaging Compared to Traditional Methods

Compared to traditional corrugated boxes, wrap-around technology offers several advantages.

Save on Packaging Materials

Wrap-around packaging machines use flat cardboard blanks that are wrapped tightly around products. This reduces corrugated cardboard needs by up to 15–20% compared to traditional boxes, meaning direct savings in material costs and lower environmental impact.

More Efficient Logistics

Wrap-around boxes take up less space in transport than traditionally formed boxes, making logistics and especially transportation more efficient. Less air is transported and more products.

Flat wrap-around blanks free up warehouse space for other uses and reduce the need for external storage. Additionally, transporting flat blanks is more efficient; more blanks fit into one load, reducing transport trips and costs while decreasing the carbon footprint of transportation.

More Protective Packaging

Tight packaging wrap effectively protects products from impacts and dirt during transport and storage, reducing the risk of product waste. Companies utilizing wrap-around packaging machines can improve delivery reliability and reduce logistical disruptions caused by waste.

Streamlined Packaging Line

The wrap-around packaging machine performs box formation, filling, and closing with single packaging machine, which means optimized space utilization in production.

Suitable for Food Industry Requirements

At Orfer, we understand the special needs of the food industry. With over 50 years of experience, we know that secondary packaging equipment must be not only efficient but also cleanable and reliable.

Easily Cleanable Packaging Machine

Wrap-around packaging machines are designed with easy cleaning in mind, using industry-standard materials such as stainless steel and open structures that minimize dirt accumulation and facilitate cleaning.

Gentle Handling

We ensure that product transfer and packaging happen in a controlled and gentle manner, protecting primary packaging and its contents from damage. This means that Orfer's packaging machines can handle and pack even fragile products gently. Orfer machines feature standard soft stop and return functions, allowing the packaging machine to be stopped without creating additional waste.

Reliability and Traceability

The cornerstones of Orfer's automation systems are reliability and product traceability. We integrate necessary additional equipment as a seamless part of our customer's production line.

Flexible and Cost-Effective Wrap-Around Packaging Machines

Today's markets demand flexibility. The wrap-around packaging machine offers the ability to handle various products and packaging formats. Quick and easy format changes minimize production interruptions when switching from one product or package size to another. Rapid product changeovers are especially beneficial in productions where batch sizes are decreasing and product ranges are expanding.

The technology is also excellently suited for manufacturing shelf-ready SRP or RRP retail packages (SRP = Shelf-Ready Packaging / RRP = Retail-Ready Packaging) that meet retail requirements, improving product display and shelving efficiency.

In addition to material savings, benefits accumulate from optimized logistics, potentially smaller workforce requirements, energy efficiency of modern machines, and high availability and reliability that reduce unexpected downtime and repair costs. Furthermore, these wrap-around packaging machines are designed to be user-friendly and require only minimal training to operate.

Packaging Automation Partner with Over 40 Years of Experience

Orfer is a family company founded in 1970 and a leading supplier of secondary packaging and internal logistics automation for the food industry. Orfer has been manufacturing packaging machines for over forty years – since 1984. Our renowned Orfer Formeca secondary packaging machines and case formers have enhanced our customers' packaging operations across various industries globally.

We deliver reliable and cost-effective automation systems that we care for with an uncompromising service attitude throughout their entire lifecycle – 24/7 when necessary. True to our promise, our solutions save space, packaging materials, and the environment.

Summary

A wrap-around packaging machine is a strategic investment for a manufacturing company seeking better efficiency, lower operating costs, and more sustainable operations. It offers a concrete solution for material savings, logistics optimization, and increased production flexibility, while meeting strict hygiene and quality requirements. Orfer's automation systems are integrated as a seamless part of the customer's production line, from packaging to palletizing and pallet load handling.

When you want more information about how Orfer's Formeca wrap-around packaging machines and other automation systems can enhance your specific production, contact our experts.

Learn More About Orfer Formeca Wrap-Around Group Packing Machines

Frequently Asked Questions about Orfer Formeca Packaging Machines

What kinds of packaging can be formed by using the wrap-around packing machines?

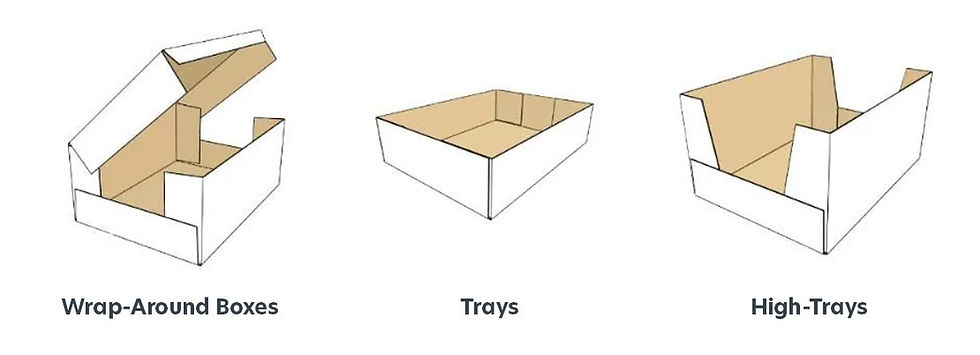

Orfer’s group packing machines can be used for various FEFCO box designs. Our specialists help you find the right packaging solution, even if you don’t know the FEFCO code of the group package. If you already have a specific packaging in mind, you can send us an image of it along with your quote request.

What is the size of packaging produced by Orfer’s group packing machines?

Tray sizes:

Minimum packaging size 230 x 80 mm, maximum packaging size 500 x 400 mm

Wrap-around box sizes:

Minimum packaging size 230 x 80 mm, maximum packaging size 450 x 400 mm

What kinds of premises are suitable for wrap-around packing machines?

Indoor production premises are suitable for group packing machines. You should reserve at least 10 m2 of floor space for the machine, depending on the machine model. In addition, reserve approximately one meter around the machine in all directions.

The height of the group packing machines is approximately 250 cm. The indoor temperature should be +3–30°C. The normal humidity in the production premises should not exceed the dew point. Otherwise, this should be mentioned to our specialist.

We do not provide solutions for ATEX premises (explosive atmospheres).

Can the wrap-around packaging machines withstand dust, and can they be cleaned?

The reliability and long lifecycle of Orfer’s packaging machines are a given for us. The special requirements of the operating environment are taken into account in the design of the machines. The benefits of Orfer’s group packing machines include usability, easy cleaning and serviceability.

What is the capacity of Orfer’s group packing machines?

The product, product group and product variation are the biggest factors affecting the capacity. Our machines automatically adapt to the line speed. Our specialist will help you find the machine best suited for your needs.

For what kinds of hygiene requirements are Orfer’s wrap-around packaging machines suitable?

Secondary packaging and intralogistics solutions are our core expertise. We ensure compliance with hygiene requirements when processing secondary packaging for food products.

What happens in the case of a failure?

The packing machine stops in a controlled manner in the case of a failure. The machine indicates the failure status by means of a light beacon and on the touchscreen, giving instructions on how to proceed. After the machine has come to a standstill in a controlled manner, the electric lock of the door will be released, and the failure can be cleared safely. The machine uses a soft start to continue production rapidly, making any unplanned standstills shorter. Orfer also offers the oCare 24/7 remote support service.

Where are Orfer’s wrap-around packing machine manufactured?

Orfer’s Formeca wrap-around packaging machines are designed, manufactured and tested in use in Finland. We only use responsible cooperation partners.

Can the user interface be modified?

Orfer’s informative user interface can be modified to provide the required languages and user levels.

How long does it take to change the packaging size?

The machines include an adjustment mechanism and switching programs for rapid changing. Changing the product size typically takes approximately 15–20 minutes. Automatic size changing is available as an option for the group packing machines, shortening the time required for adjusting the product size.

What does SRP packaging mean?

Wrap-around boxes are very often SRP boxes, or shelf-ready packaging. This means that the transport packaging becomes a display packaging when unnecessary sections are removed along the perforated lines during shelving.